:Consumer Hotline:

:Consumer Hotline:

022 - 5921 - 3388

E-mail:

sales@attl.cn

Products Back

Heat Sinks for Electronic PackagingBack

Hotzone Parts in Sapphire GrowerBack

Ceramics and OthersBack

Applications Back

Application:

Application:

Quartz glass is silicon dioxide constituent of glass whose hardness can reach Morse seven levels. It has a series of excellent physical and chemical properties: high temperature resistance, low expansion coefficient, heat shock resistance, chemical stability and good electrical insulation, and ultraviolet and infrared lights can pass through.

Material Properties:

Material Properties:

Tungsten has the characters of high melting point, high strength at elevated temperature, low electrical resistivity, lower thermal expansion, low work function of electron emission and low vapor pressure.

Product specification:

Product specification:

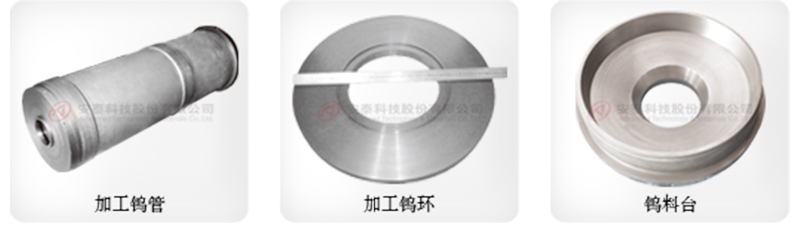

Tungsten Tubes: we can produce the largest tungsten tube in the world. OD=780mm

Conventional Density: 17.8 g/cm3-18.3 g/cm3

Special Process Density: ≥18.5 g/cm3

Typical Specifications of Tungsten Tube:

Diameter(mm)

Wall Thickness(mm)

Length(mm)

≥30

≥2

≥1300

≥150

≥5

≥300

≥10

≥400

≥15

≥800

≥35

Note: All sizes of tungsten tubes can reach high precision by machining.

Tungsten Mandrel Shalfs: After forging,the length of Mandrel Shalfs can be L≤2500mm, Diameter≤80mm.

Our Advantages:

Our Advantages:

- We have the 60 years experience of Central Iron & Steel Research Institute, own the professional tungsten and molybdenum manufacture technology and is the first supplier of tungsten tube in China.

- We have the nation's largest advanced tungsten & molybdenum materials production lines which can satisfy your different product requirements.

- Precision machining technology, the use of CNC laser cutting, high precision, to ensure that the heat evenly spaced, provides the high quality products for quartz continuous melting furnace.

- We can design and improve the furnace together with you. We have more than 20 thermal field technology engineers always ready for your production line, make recommendations for you.

- We never stop footsteps of Technical innovation. As a state-owned company, we take responsibility of leading the development of domestic refractory metal technology.

- Company certificated by the ISO9001, ISO14001 and OHSAS18001 system authentication.